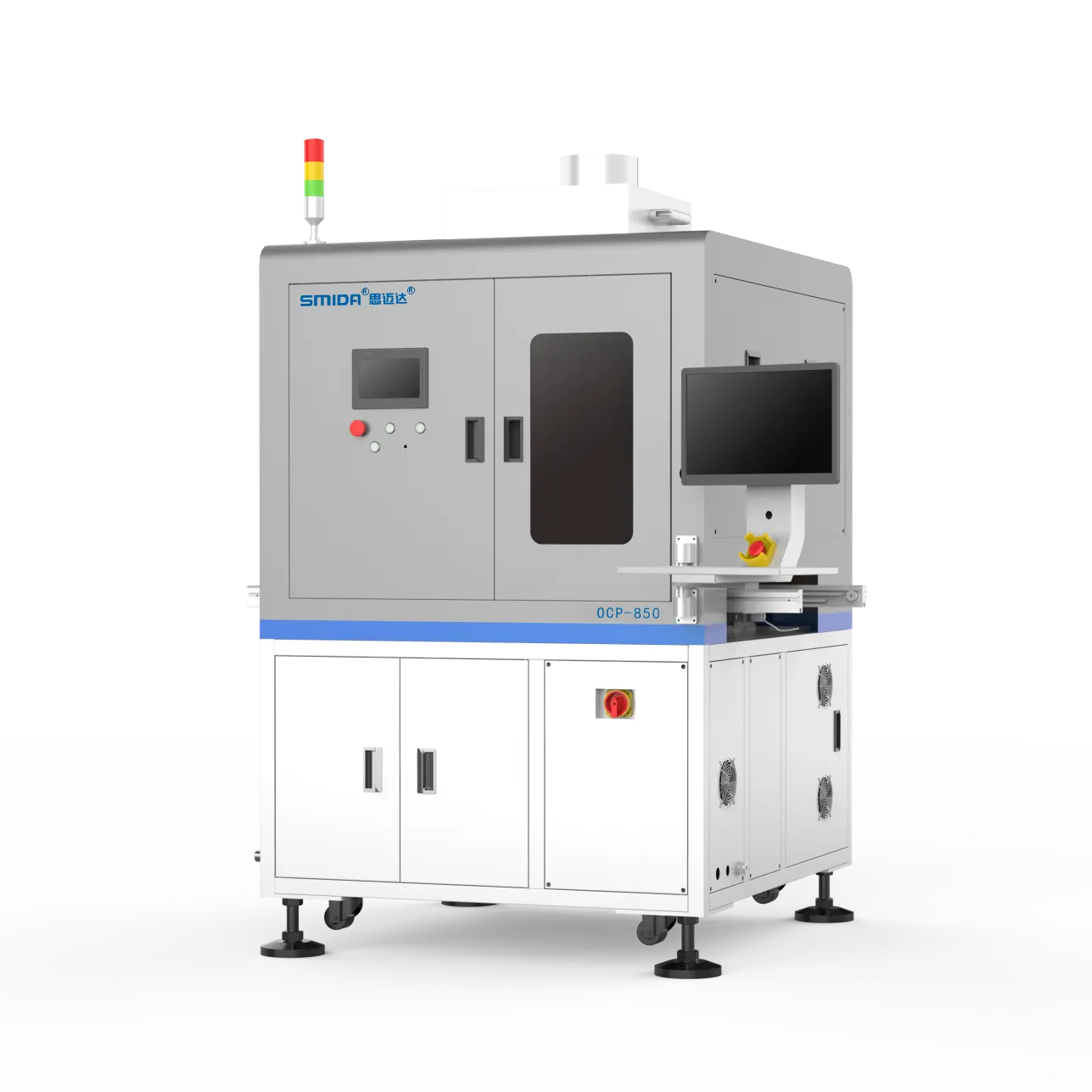

Material Surface Treatment Equipment Plasma Cleaning Machine SMIDA OCP-850

The clean and highly active surface obtained after processing makes bonding, spraying, and printing easier, thereby improving processing quality, reducing processing costs, and increasing processing efficiency.

Plasma Cleaning Machine

OCP-850

——————

Cleaning Scope

L200-1200mm (> 850mm requires assistance from a docking station), W200-550mm

Cleaning Head

4

Clean the Corners of Water Droplets

20°-50°

Working Mode

Online, supports left in and right out, right in and left out, left in and left out, right in and right out

Highest Accuracy

±0.05mm

You can contact SMIDA for issues related to plasma surface treatment and plasma cleaning.

With the continuous development of science and technology and the increasing demand for traditional material properties in some high-tech fields, plasma technology has been widely applied in cutting-edge technology fields such as materials science, polymer science, biomedical, environmental science, and optical materials due to its advantages of short time, high efficiency, and energy conservation and environmental protection.

Advantages of SMIDA

plasma cleaning machine

Plasma cleaning modification only occurs on the surface layer of the material, does not affect the inherent properties of the substrate, and has good treatment uniformity.

By using plasma to perform nanoscale micro etching on the surface of an object, the smoothness of its surface can be reduced, greatly improving adhesion.

By using plasma to activate the surface of materials, the hydrophilicity and activity of the material surface are stimulated, thereby improving the strength of adhesive bonding.

Online processing to meet the requirements of wiring.

Suitable for Mini direct display, Mini backlight, adhesive film, glass substrate, OCA, PET, PC, FPC and other materials.

For details, please contact SMIDA

Main technical parameters of the machine

Model |

OCP - 850 |

Product Name |

Plasma Cleaning Machine |

Cleaning Range |

L200 - 1200mm (Auxiliary stage required for >850mm), W200 - 550mm | ||

Working Mode |

Online type, supporting left-in-right-out, right-in-left-out, left-in-left-out, right-in-right-out | ||

Cleaning Water Drop Angle |

20° - 50° |

Cleaning Head |

4 pcs |

Highest Precision |

±0.05mm |

Platform Repeatability |

±0.05mm |

Comprehensive Precision |

±0.1mm |

Working Height |

900±30mm |

Y-axis Stroke |

650mm |

Z-axis Stroke |

50mm |

Max. Speed of Y/Z Single Axis |

500mm/s |

Working Environment |

Temperature 25℃±2℃; Humidity ≤60%; No condensation |

Industrial Dust Collection System |

Standard configuration |

Operating System |

SMIDA |

Main Equipment Power Supply |

220V,50Hz |

Total Power |

6.5KW |

Overall Dimension of Main Equipment |

L1460*W1720*H1830mm |

Weight |

520kg |