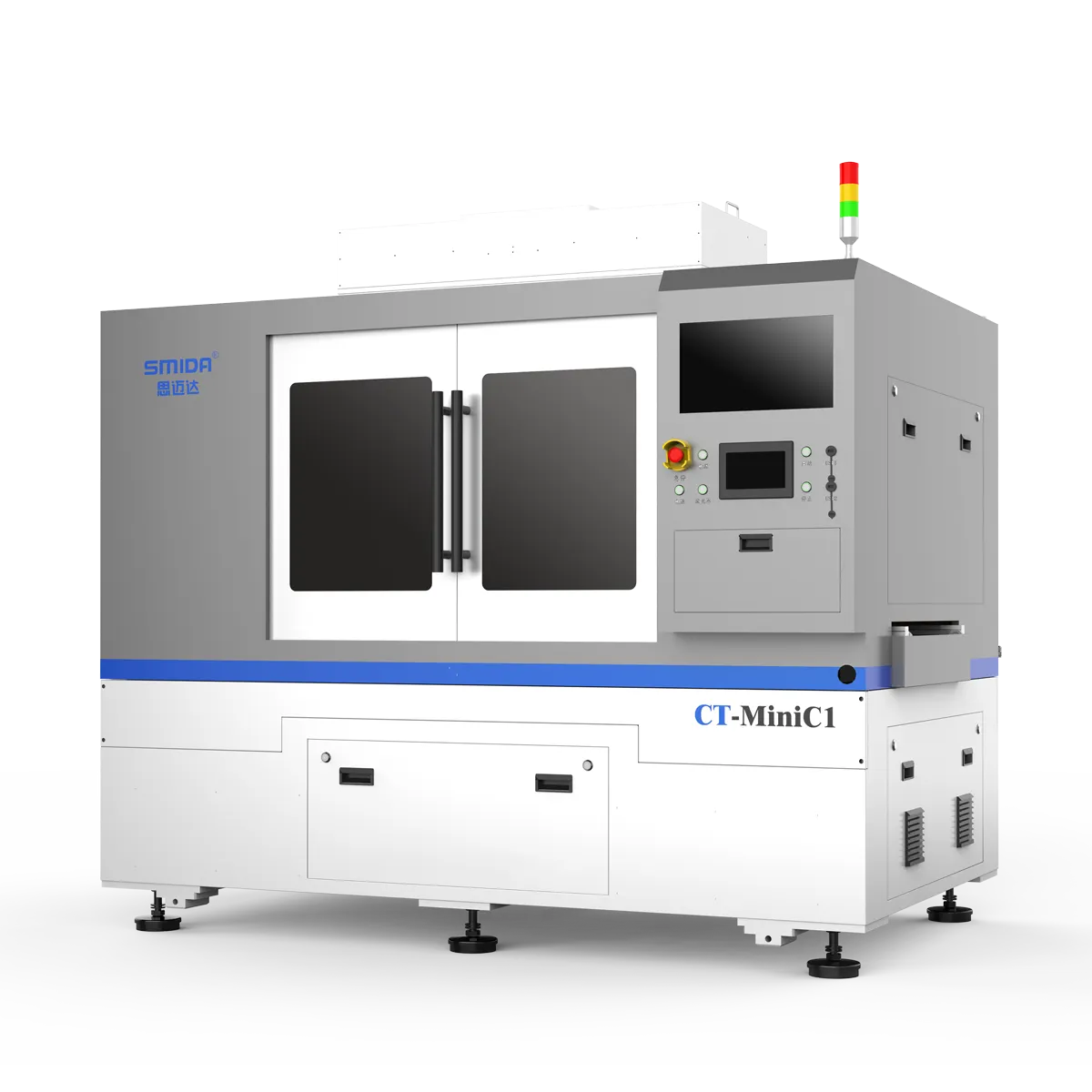

Online Fiber Optic Metal Laser Sub-board Cutting Machine CT-MiniC1

Online laser sub-board machine adopts an online working mode, with a two-stage track conveyor that can automatically adjust the width. It is also compatible with multiple board entry and exit methods such as left in and right out, left in and left out, reducing personnel operation.

About CT-MiniC1

CT-MiniC1 is an online laser sub board machine.

We use fiber lasers with good optical modes and long lifetimes, which can cut metal materials below 2mm. The laser power can be selected according to the cutting material.

Online working mode, compatible with left in and right out, right in and left out, left in and left out, right in and right out, equipped with a dedicated industrial control computer, the entire process is automatically controlled by computer software, and the operation is simple.

Technical Parameter

Online laser sub-board machine

CT-MiniC1

| Configuration indicators | Parameter |

| Cutting heads | 2D/3D cutting head optional |

| Online working mode | Two section rail conveyor with automatic width adjustment |

| Cutting system | SMIDA |

| File formats | dxf format |

| MES system connection | Reserved interface, optional with customized information collection |

| Industrial vacuum cleaning system | Standard configuration |

| High-pressure air source (dry filtered air) | 1.2Mpa-1.5Mpa |

| Air source (dry filtered air) | 0.5-0.6Mpa |

| Online line height | 900±30mm |

| Rated voltage of main equipment power supply | 220V/50Hz |

| Industrial vacuum power supply | 380V/50Hz |

| Main equipment dimensions (L*W*H) | 2405x1560x2140(mm) |

| Weight | 2400kg |

| Total power | 9.3kW/h (including vacuum cleaner) |

| Work environment | Temperature 25 ℃± 2 ℃; Humidity ≤ 60% |

This table is for reference only. Actual dimensions are subject to the actual product. Changes in product appearance and specifications are not notified.ent industries.

Performance index

| Platform structure | marble+linear motor |

| Positioning accuracy | ± 3um |

| Repetitive positioning accuracy | ± 1.5um |

| X/Y resolution | 0.2um |

| CCD resolution | 5 million pixels |

| Scanning function | optional |

| X-axis travel |

1340mm |

| Y-axis travel |

680mm |

| Z-axis travel |

100mm |

| X. Y-axis maximum speed | 1000mm/s |

| XY maximum acceleration | 1.5G |

This table is for reference only. Actual dimensions are subject to the actual product. Changes in product appearance and specifications are not notified.ent industries.

Application

Metal materials such as aluminum substrate, copper substrate, aluminum alloy, stainless steel, carbon steel, alloy steel, silicon steel, etc.

COMPANY STRENGTH

| Performance index | Parameter |

| Machine name | |

| Machine model | |

| Laser type | |

| Laser power | |

| Platform processing cap surface (L*W) | |

| Machinable material thickness | |

| Cutting heads | |

| Online working mode | |

| Industrial vacuum cleaning system | |

| File formats | |

| MES system connection | |

| Cutting system | |

This table is for reference only. Actual dimensions are subject to the actual product. Changes in product appearance and specifications are not notified.

What you need to know about product accuracy

| Platform structure | marble+linear motor |

| Positioning accuracy | ± 3um |

| Repetitive positioning accuracy | ± 1.5um |

| X/Y resolution | 0.2um |

| CCD resolution | 5 million pixels |

| Scanning function | optional |

| X-axis travel |

1340mm |

| Y-axis travel |

680mm |

| Z-axis travel |

100mm |

| X. Y-axis maximum speed | 1000mm/s |

| XY maximum acceleration | 1.5G |

This table is for reference only. Actual dimensions are subject to the actual product. Changes in product appearance and specifications are not notified.