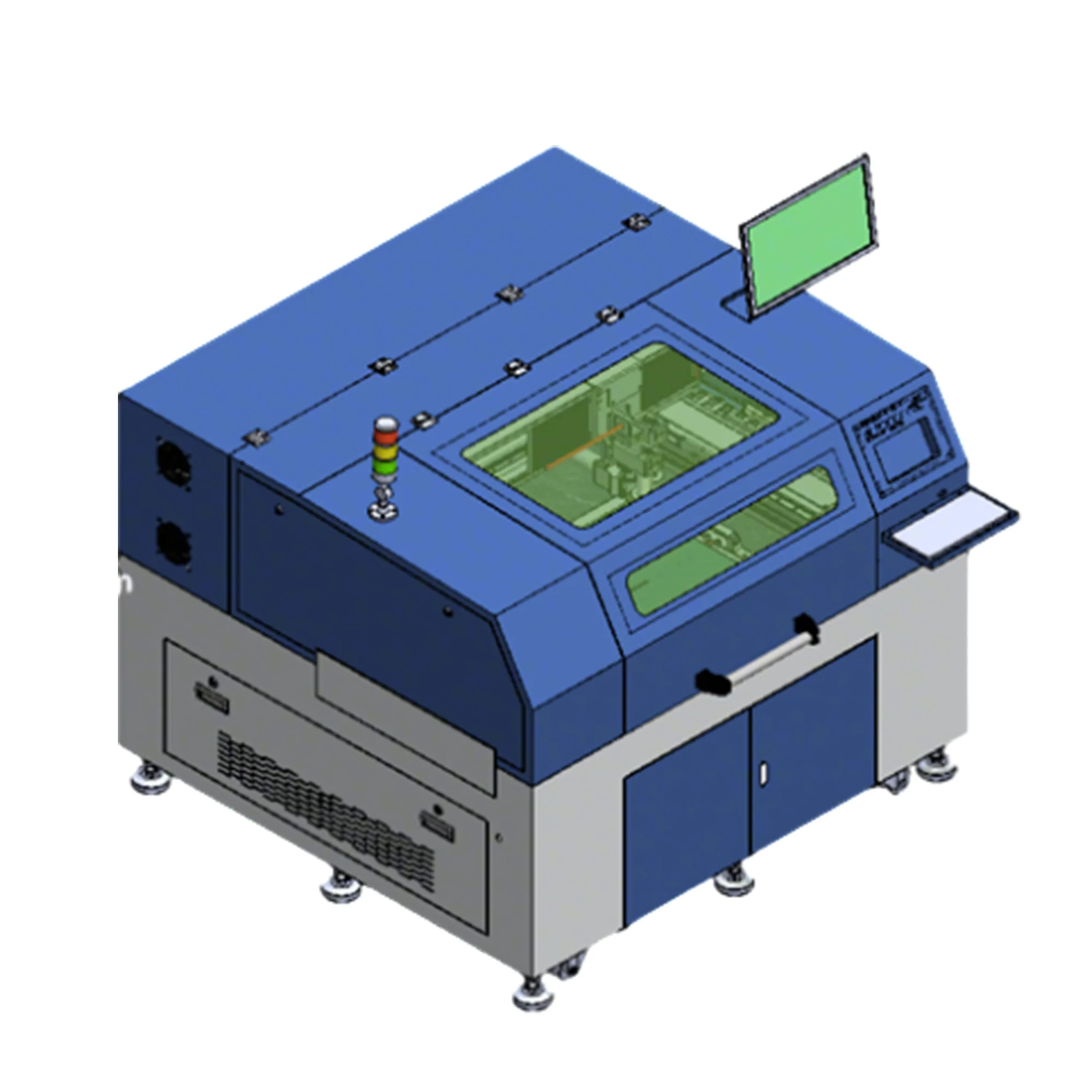

SMIDA Non metallic cutting CO2 laser cutting machine high-precision processing equipment CT-DCM-6555

CT-DCM-6555 uses a carbon dioxide laser as its key component, which has many significant advantages such as high cutting quality, ultra-high precision, excellent cutting edge, and minimal thermal impact; Fast cutting speed, far exceeding traditional cutting methods; Cutting materials are extensive, covering both metal and non-metal materials; Strong flexibility, controllable complex programming paths, suitable for small batch production; High degree of automation, CNC system ensures precise cutting; Also environmentally friendly and energy-efficient. Therefore, it is widely used in various fields such as industrial manufacturing, advertising, packaging, textile and clothing, and effectively promotes the development of various industries.

Non metallic material dedicated laser cutting machine

Main features:

1. High cutting quality

2. Fast cutting speed

3. Wide range of materials

4. High flexibility

5. High degree of automation

6. Environmental protection and energy conservation

1 unit for sale | 1 unit for customization

Support for multiple purchases | Global after-sales service

CO2 Laser Cutter

| Serial Number | Performance Indicators | Parameter |

| 1 | Machine name | CT-DCM-6555 |

| 2 | Model | CO2 laser cutting machine |

| 3 | Cutting range | 650*550mm |

| 4 | Positioning accuracy | ±20um |

| 5 | Comprehensive precision | ±50um |

| 6 | Laser type | Carbon dioxide RF laser |

| 7 | Laser power | 60W-150W |

| 8 | Wavelength | 9.3um/10.6um |

| 9 | Cooling method | Water/Air Cooled |

| 10 | CCD resolution | 500W |

| 11 | X-axis travel | 650mm |

| 12 | Y-axis travel | 550mm |

| 13 | Maximum X/Y single-axis speed | 800mm/s |

| 14 | Industrial vacuum system | Standard |

| 15 | File format | dxf format |

| 16 | Cutting system | SMIDA |

| 17 | Mains equipment supply voltage | 220V/50Hz |

| 18 | Air source (dry filtered air) | 0.5-0.6Mpa |

| 19 | Equipment external dimensions | L1550*W1470*H1105mm |

| 20 | Working environment | Temperature: 5℃-35℃; Humidity ≤60 |

| 21 | Weight | 1000kg |

Total power

Equipped with high power CO2 laser for high speed cutting efficiency.

Marble high-precision screw platform to meet the rapid cutting efficiency and effectiveness.

X/Y table adopts dynamic gantry structure, marble base, flying light path design, high stability.

The suction system can eliminate all the cutting exhaust gases, avoiding the hazards to the operators and pollution to the environment.

Total power

Fast cutting speed, good quality, high precision, meeting high-speed cutting efficiency.

High precision platform structure, high processing accuracy, and stable equipment performance.

Wide adaptability, able to cut most non-metallic materials and some metallic materials.

Non contact cutting eliminates damage caused by tool or material stress processing.

The suction system eliminates cutting waste gas and avoids the impact on personnel and the environment.