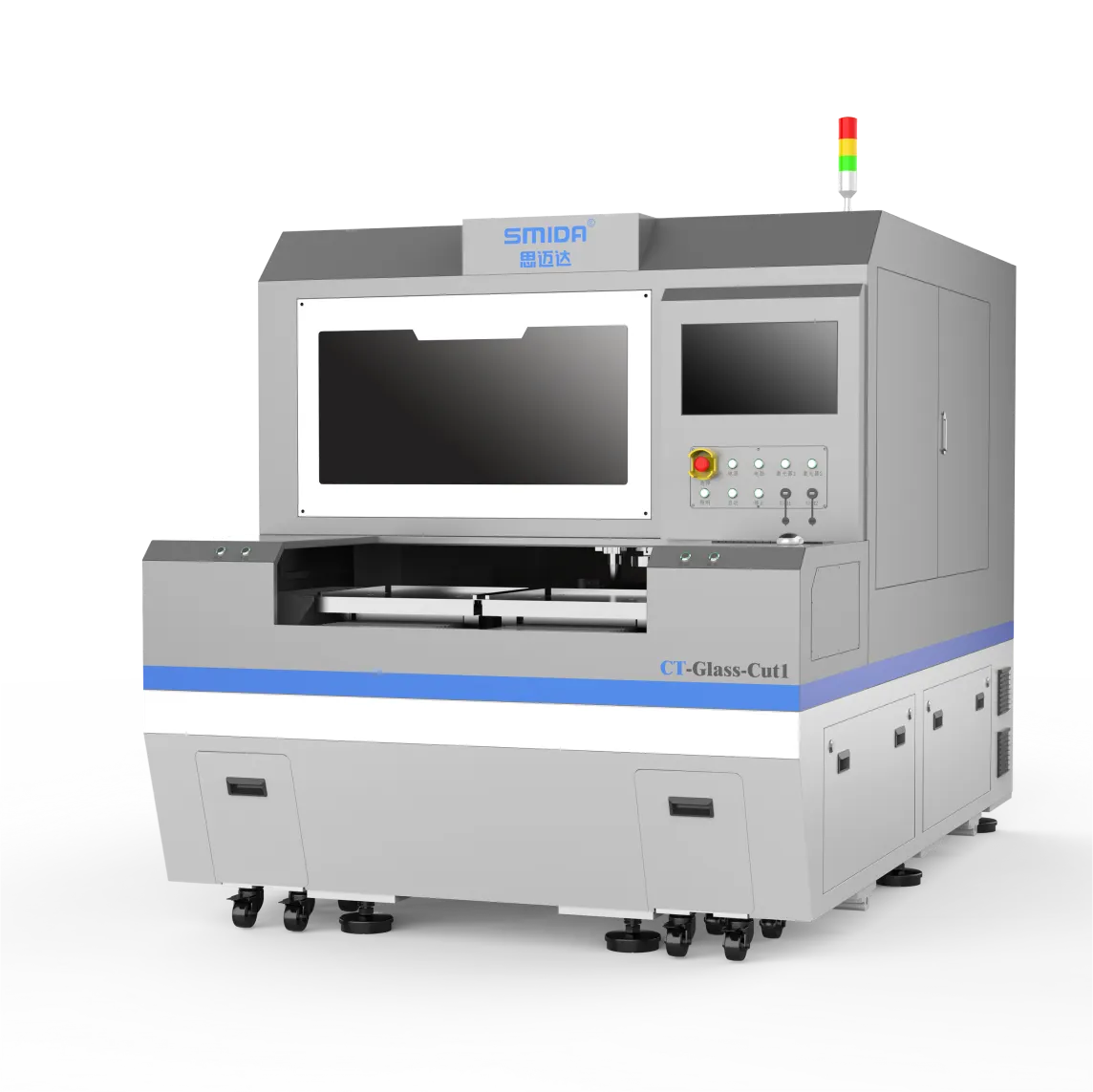

Glass Ceramics Laser Cutting and Splitting Machine CT-Glass-Cut1

- Advanced core technology

1. Using high-performance lasers to achieve micrometer level cutting accuracy, with smooth and burr free edges.

2. SMIDA autonomous control system, directly importing DXF files for rapid prototyping, cutting, and drilling.

3. CCD image automatic recognition and high-precision image positioning ensure the consistency and stability of cutting.

- Efficient production capacity

1. Non contact operation, fast cutting speed, suitable for large-scale and continuous production.

2. Reduce the waste and mechanical wear associated with traditional cutting tools, making them more energy-efficient and environmentally friendly.

3. Support diverse processing methods beyond straight and curved cutting, such as punching and carving.

About CT-Glass-Cut1

CT-Glass-Cut1 is a machine specifically designed for laser cutting and slicing of materials such as glass and ceramics.

Equipped with high-performance infrared picosecond laser and VO2 laser, cutting and splitting are carried out simultaneously to improve production efficiency.

In short, our glass laser cutting machine has become the preferred equipment in the modern glass processing industry due to its excellent performance, efficient production capacity, and wide range of applications. We are committed to providing our customers with the highest quality products and services, helping enterprises achieve industrial upgrading and transformation.

Performance Index

Laser Cutting and Splitting Machine

CT-Glass-Cut1

| Performance Index | Parameter |

| Product name | Laser cutting and splitting machine |

| Working mode | Manual loading and unloading |

| Cutting system | SMIDA |

| File format | Dxf format |

| Purpose | Glass and ceramic cutting |

| Industrial vacuum cleaning system | Standard configuration |

| Work environment | Temperature 25 ℃+2 ℃; Humidity ≤ 60% |

| Air source (dry filtered air) | 0.5-0.6Mpa |

| Working height | 870+30mm |

| Rated voltage of main equipment power supply | 380V/50Hz |

| Industrial vacuum power supply | 380V/50Hz |

| Equipment dimensions (L*W*H) | 1730x2700x1860(mm) |

| Weight | 4200kg |

| Total power | 13kW/h (including vacuum cleaner) |

This table is for reference only. Actual dimensions are subject to the actual product. Changes in product appearance and specifications are not notified.ent industries.

Equipment Selection Function

In order to meet the cutting needs of different customers, Smida offers some optional functions.

Technical Parameter

| Performance Index | Parameter |

| Platform structure | Marble+linear motor |

| Positioning accuracy | ±3μm |

| Repetitive positioning accuracy | ±1.5μm |

| X/Y resolution | 0.1um |

| Cutting head | Bessel cutting head |

| CCD resolution | 5 million pesos |

| X1/X2 axis travel | 950mm |

| Y1/Y2 axis travel | 1930mm |

| Z-axis travel | 50mm |

| X1, X2, Y1, Y2 single axis maximum speed | 800mm/s |

| XY maximum acceleratio | 1.0G |

This table is for reference only. Actual dimensions are subject to the actual product. Changes in product appearance and specifications are not notified.ent industries.

Application

Cutting of thick glass, large format irregular cutting, optical glass, optical edge, smart device glass cover, camera protective lens, eye lens, etc