Planetary Centrifugal Vacuum Mixer Vacuum Type Wholesale - Smida

Product details of the planetary centrifugal vacuum mixer

Quick Detail

Smida planetary centrifugal vacuum mixer is designed by a team of professionals who have extensive industry knowledge and clearly know customer needs. The quality of this product can not be assured without the efforts of each Smida staff. planetary centrifugal vacuum mixer developed and produced by Smida is widely applied to many industries and fields. It can fully meet the diversified needs of customers. The application prospects of this product become more and more extensive.

Product Information

Next, the details of planetary centrifugal vacuum mixer are shown for you.

Vacuum Planetary Centrifugal Mixer

Shenzhen Smida lntelligent Equipment Co., Ltd.

TMV-2000TT Epoxy Mixing Machine

· Revolution speed - up to 2500rpm

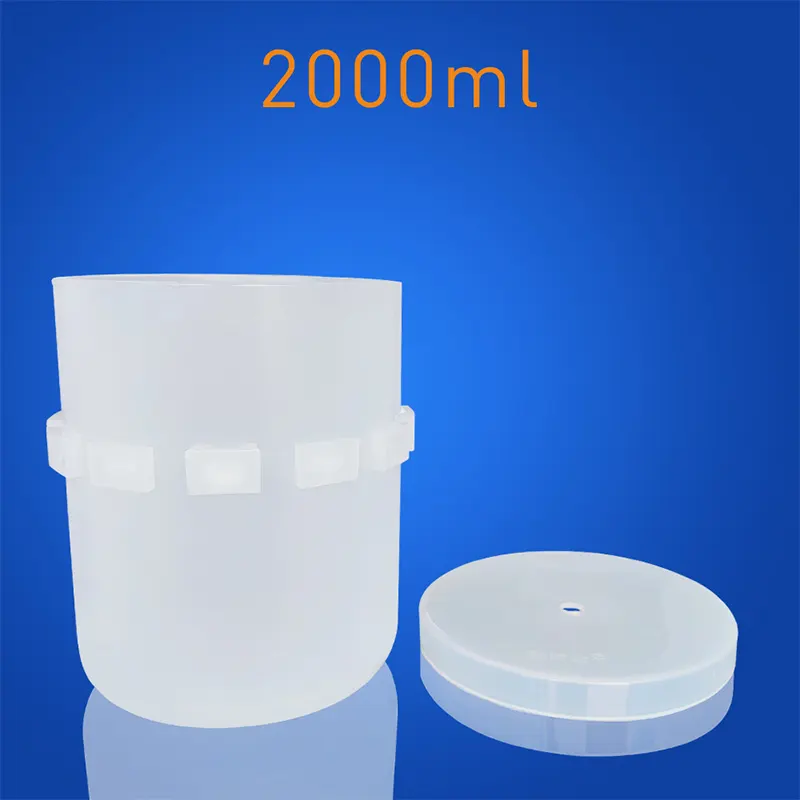

· Mixing capacity - up to 2000ml

· Material weight - up to 2000g per time

· Motor power - up to 2.8kW

· Equipment size - L730*W730*H910mm

· Equipment weight - 215kg

Reasons to Select a Smida Planetary Centrifugal Mixer

High Speed

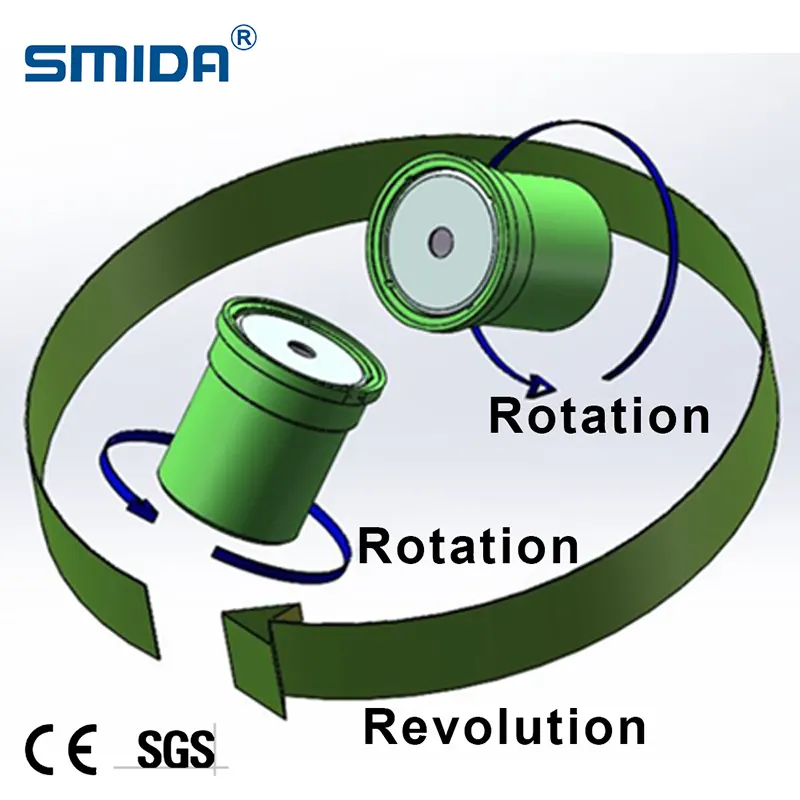

The planetary centrifugal vacuum mixer operates at revolution speeds up to 2500 rpm, creating strong shear forces that break down particles and droplets. This ensures fast, thorough mixing and deaeration, which is crucial for blending fillers or additives into epoxy formulations.

Streamlined process

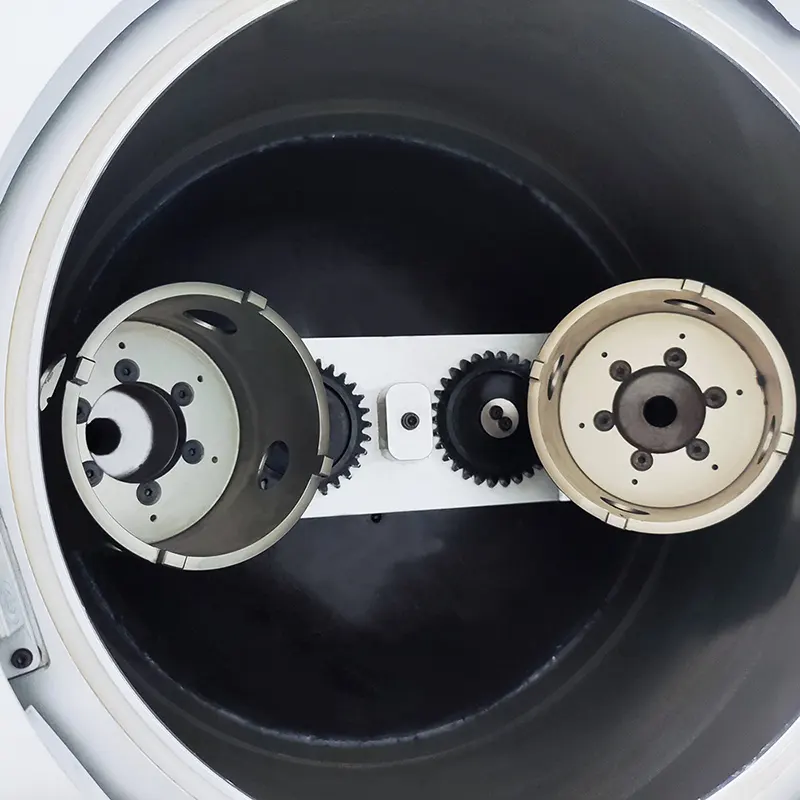

Generated by the revolving and rotating of the containers, the dual centrifugal forces can mix and defoam materials thoroughly without the need mixing rods, blades or media. This saves the cleaning process between batches. Meanwhile, the built-in vacuum pump removes bubbles effectively during mixing, removing the need for separate steps. These features can dramatically reduce processing time.

Enhanced Product Homogeneity

The resin planetary centrifugal mixer is designed to ensures all components—such as resins, hardeners, fillers, and additives—are evenly distributed throughout the epoxy formulation. This uniformity is critical for achieving consistent performance and quality, minimizing variations that could impact the epoxy’s curing properties and adhesion strength.

Adjustable Revolution-to-Rotation Speed Ratio

By adjusting the ratio, users can optimize the mixing dynamics to achieve precise results for various formulations and applications.

Ease of Handling and Installation

The relatively light weight (215kg) and compact size make this resin mixer machine easier to transport, install, and reposition within a facility. This is beneficial in limited spaces or when equipment needs to be frequently moved.

Uses

This epoxy planetary centrifugal vacuum mixer is typically used for the efficient dispersion, mixing, and deaeration of multi-component materials, particularly epoxy resins. Beyond epoxies, its applications extend to a wide range of materials, including polyester resins, coatings, adhesives, potting compounds, paint coatings, slurries, and pastes. This mixer is an essential asset for production plants across various industries, ensuring consistent quality and streamlined operations.

The resin centrifugal mixer excels in handling a diverse range of materials and processing tasks. It is especially effective for:

1) Mixing two or more liquids with significantly different properties or densities.

2) Mixing liquids with powders, ensuring a thorough mixture even when the materials vary greatly in properties or densities.

3) Processing high-value materials that require contamination-free handling and minimal waste processing.

Resin Mixing Machine Advantages

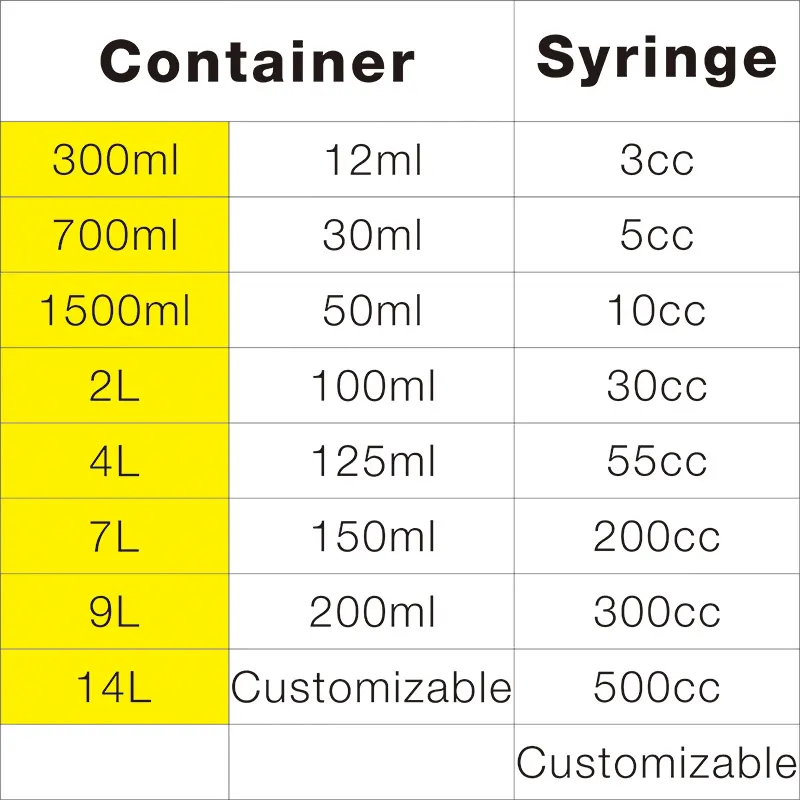

The epoxy mixing machine single mixing can mix 2000ml of large-capacity materials, which can be adjusted to different capacities through different transfer fixtures for mixing. Whether for experimental or mass production use, it can be easily met, with a mixing speed of up to 2500rpm, which can be completed in a short time. The rotation speed can be adjusted according to the characteristics of the materials to adapt to different materials. It can not only perfectly mix materials but also not damage them.

Planetary Centrifugal Mixer Description

The TMV-2000TT planetary centrifugal mixer can have many names, including epoxy mixing machine, resin mixing machine, and adhesive mixing machine. Due to its unique planetary design, this vacuum planetary mixer uses revolution and rotation for material mixing, which can mix most materials and achieve good mixing effects. The epoxy resin mixer machine is suitable for industries such as chemical, light industry, battery, and pharmaceutical.

Technical Parameter

|

Product Name |

Planetary centrifugal mixer |

|

Model |

TMV-2000TT |

|

Working mode |

Rotation, revolution, non-contact, vacuum |

|

Max. mixing capacity |

2L/2kg (2 cups) |

|

Operating speed |

Revolution: 100-2500rpm, rotation: adjustable ratio of 0-2 revolution to rotational speed |

|

Max. running time |

30mins |

|

Display method |

LCD |

|

Power Supply |

AC220V, 50Hz/60Hz |

|

Power |

2.8kW |

|

Equipment size |

730*730*910mm |

|

Equipment weight |

215kg |

Application

Planetary mixers are widely used in fields such as chemical, resin, epoxy resin, pharmaceuticals, printing inks, paint coatings, etc. Because planetary centrifugal mixers can evenly disperse raw materials with different densities and ratios in the mixing medium, forming a more uniform mixture, this characteristic is applicable to most materials.

FAQ

Company Information

planetary centrifugal vacuum mixer is manufactured by Shenzhen Smida Intelligent Equipment Co., Ltd., which has skilled workers, strong R&D ability and highly strict quality control system. With core technology, Smida has succeeded in taking this chance of developing planetary centrifugal vacuum mixer which is of high performance in planetary centrifugal vacuum mixer. Guaranteed high-quality planetary centrifugal vacuum mixer is our commitment. Check it!

The products we produced are of high quality and reasonable price. If needed, please contact us!