1.5L Temperature Control Vacuum Planetary Centrifugal Mixer SMIDA TMV-1500TTC

Planetary Centrifugal Mixer

● Mixing of material using 2 centrifugal forces in a short time.

● Mixing capacity varies from a few grams up to 1500g.

● Up to 20 preset programs for different types of the materials.

● Max. rotation speed is 2500rpm for high viscosity material.

● The key parts are all imported and the big brand in the industry.

● Some functions can be modified accrding to customer's request.

Maximum capacity: 1500ml,750g*2

Overall dimensions: (L7300*W730*H910+L280*W560*H460)mm

Revolution speed: (100-2500)rpm

Overall weight: (220+30)kg

Power supply: AC220V/(4+0.7)kW

● Mixing of material using 2 centrifugal forces in a short time.

● Mixing capacity varies from a few grams up to 1500g.

● Up to 20 preset programs for different types of the materials.

● Max. rotation speed is 2500rpm for high viscosity material.

● The key parts are all imported and the big brand in the industry.

● Some functions can be modified accrding to customer's request.

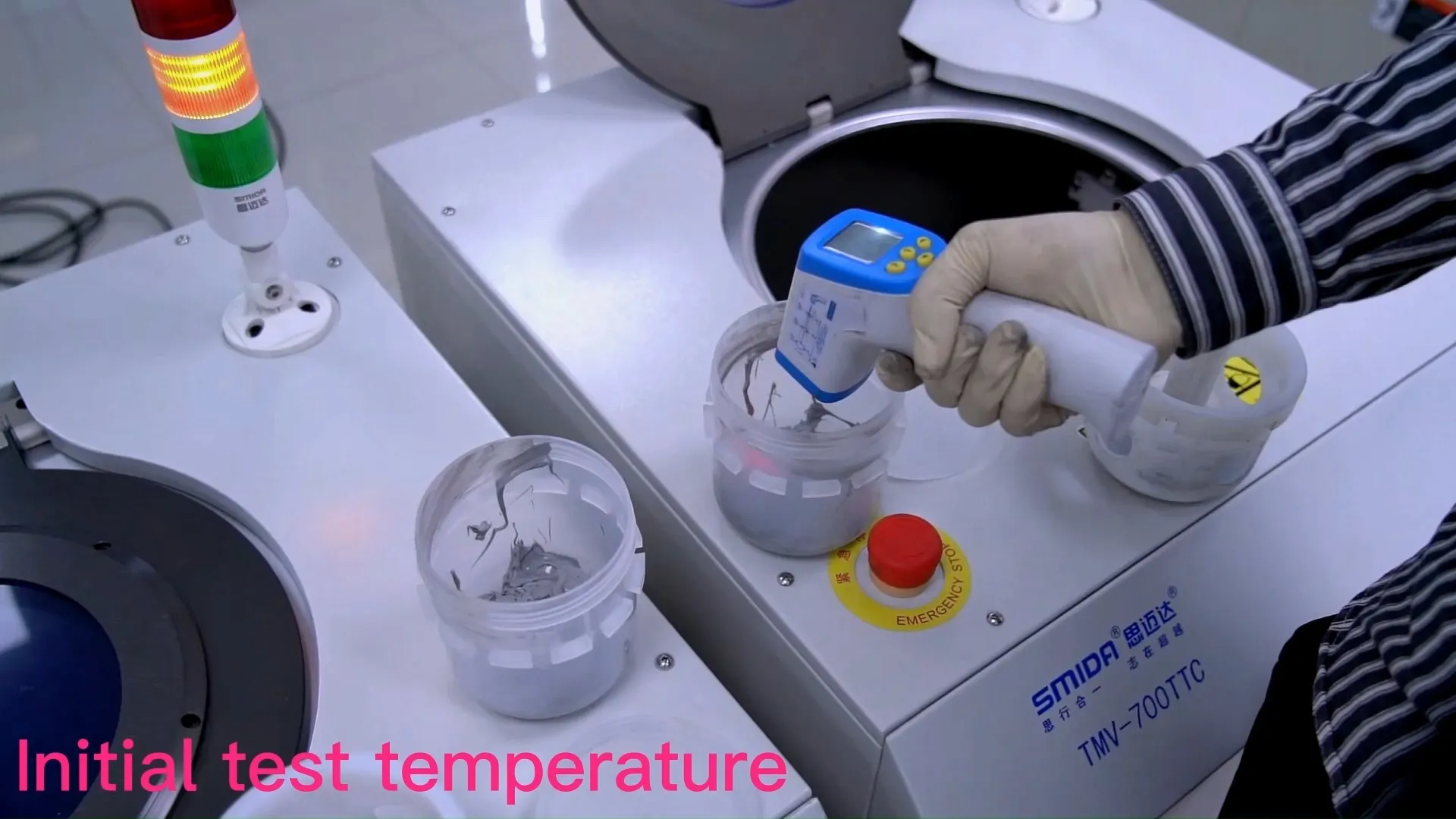

Benefits of Planetary Centrifugal Mixer with Temperature Control Feature

Enhanced product performance

The planetary centrifugal mixer with temperature control ensure optimal viscosity, bonding properties, and curing process of materials, leading to improved and consistent product quality. This is particularly important in applications involving adhesives and coatings.

Reduced risk of chemical change and degradation

Temperature control minimizes the risk of unwanted chemical reactions and thermal degradation of heat-sensitive materials, such as certain resins and active pharmaceutical ingredients. By preventing overheating, these temperature control vacuum planetary centrifugal mixers help keep formulations stable, ensuring their efficacy and safety.

Prevention of Microbial Growth

IIn pharmaceuticals, temperature control can help reduce the risk of microbial growth, ensuring the safety and hygiene of the end product.

Formulations Typically Requiring Temperature Control

Adhesives and Sealants: Many of them are temperature-sensitive, and temperature control ensures optimal bonding properties.

Coatings: Temperature affects the viscosity and curing process of paints and coatings. Correct temperature is essential for achieving consistent and desired product performance.

Pharmaceuticals: Active ingredients can be at risk of thermal degradation, and temperature control is crucial for

their efficacy and safety.

Cosmetics: Sensitive ingredients like vitamins and fragrances can degrade when exposed to high temperatures. Temperature control maintains product integrity.

Planetary Centrifugal Mixer Advantages

Product Description

Shenzhen Smidalntelligent Equipment Co.Ltd.

Automation Equipment One stop solution provider

Smida is a company with more than 10 years of production and R&D experience in the professional intelligent equipment. It is a national high-tech enterprise that integrates automation solution consulting, R&D, manufacturing, and after-sales service. We win a number of foreign trade export certification and patents, and has cooperated with many enterprises.

Technical Parameter

|

Product Name |

Planetary centrifugal mixer |

|

Model |

TMV-1500TTC |

|

Working mode |

Rotation, revolution, non-contact, vacuum, temperature control |

|

Max. mixing capacity |

1.5L/1.5kg (2 cups) |

|

Operating speed |

Revolution: 100-2500rpm, rotation: adjustable ratio of 0-2 revolution to rotational speed |

|

Max. running time |

30mins |

|

Display method |

LCD |

|

Power Supply |

AC220V, 50Hz/60Hz |

|

Power |

4kW (Water cooler: 0.7kW) |

|

Equipment size |

730*730*910mm (Water cooler: 280*560*460mm) |

|

Equipment weight |

220kg (Water cooler: 30kg) |

Application

FAQ