- No need to clean: This paint planetary centrifugal vacuum mixer operates without blades directly immersed in the material. This setup eliminates the cleaning steps between batches. This leads to significantly reduced downtime and increased operational efficiency.

- Optimal material recovery: The non-contact mechanism maximizes material recovery at the end of the process.

- Consistent result: High centrifugal force from high-speed “rotation” and “revolution” ensures thorough dispersion. Therefore, every batch can achieve consistent uniformity, leading to reliable performance.

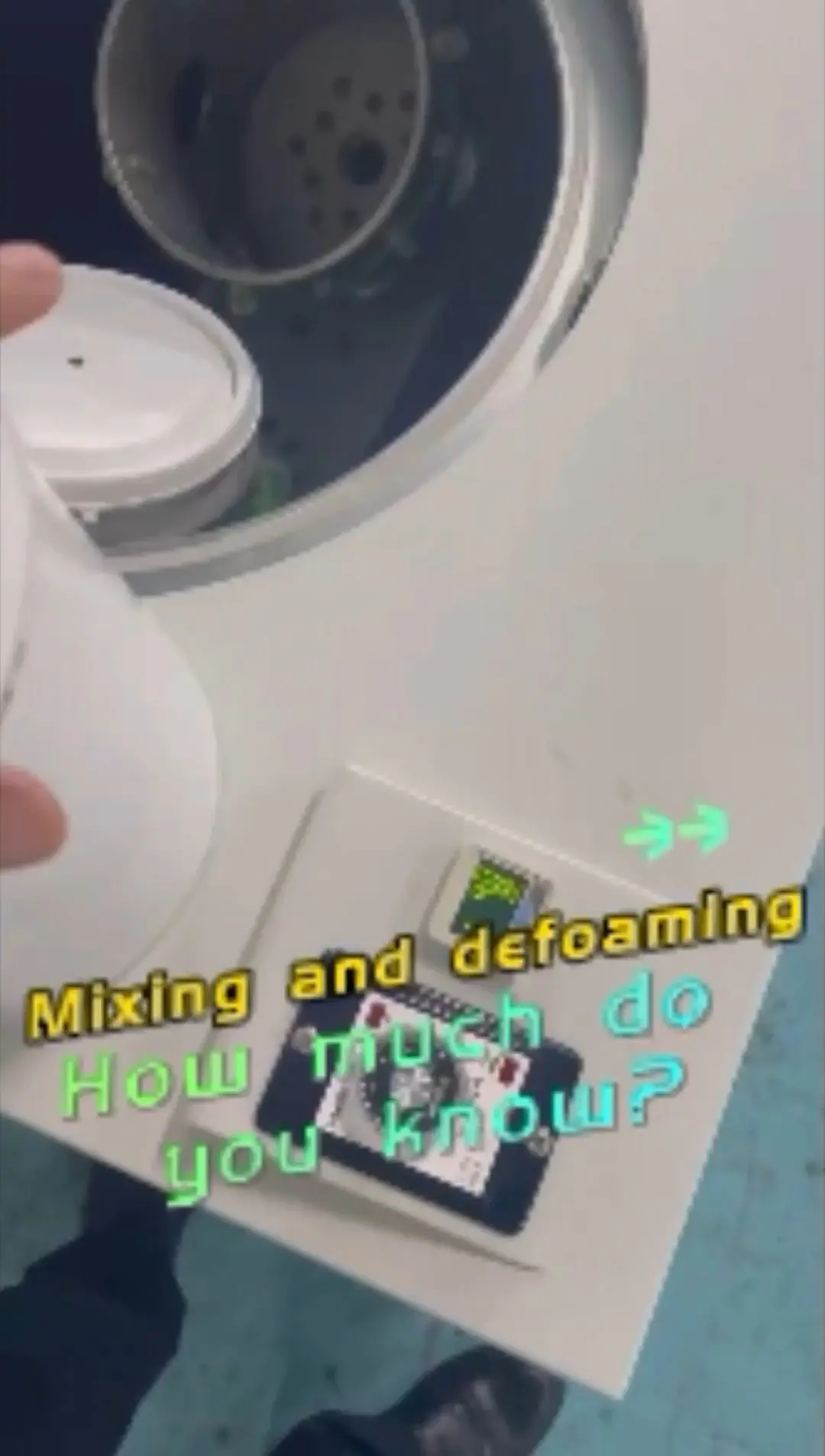

- Efficient defoaming: The high-efficiency vacuum pump can eliminate sub-micron bubbles while the materials are being mixed, in seconds to several minutes. This streamlines the process and ensures a smoother finish and prevents oxidation.

- Wide range of processing: This paint mixer is capable of handling material quantities from as little as 1g up to 7kg, minimizing materials waste. This Scalability makes it ideal for both small sample testing and large-scale production.

- Lower maintenance costs: The paint mixer requires less maintenance because it lacks submerged components that are prone to wear and tear.