- Specifically designed for the beauty sealant industry, ensuring precision and efficiency.

- Capable of stirring up to 7 kg in a single batch, providing consistent product quality from initial sample tests to scaling up for larger production volumes.

- Features adjustable time, speed, and vacuum settings, allowing for precise customization according to the properties of different materials.

- Equipped with an intuitive touchscreen control panel and advanced microprocessor, providing user-friendly operation.

- Delivers high-speed mixing that ensures even blending in minimal time, enhancing productivity.

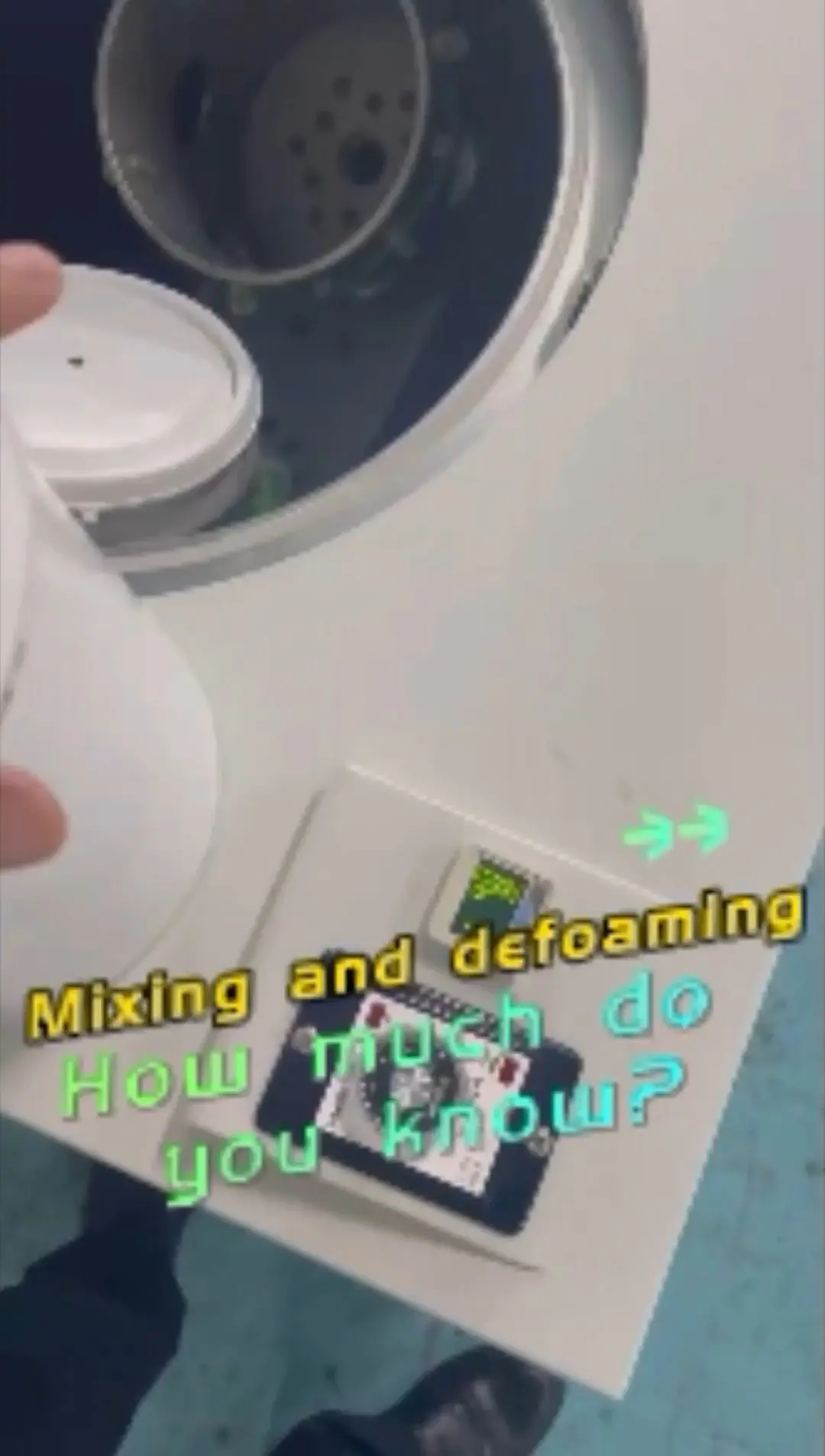

- Eliminates submicron-level bubbles while completing mixing quickly, ensuring a uniform color and a bubble-free mixture.

- No need to clean: This paint planetary centrifugal vacuum mixer operates without blades directly immersed in the material. This setup eliminates the cleaning steps between batches. This leads to significantly reduced downtime and increased operational efficiency.

- Optimal material recovery: The non-contact mechanism maximizes material recovery at the end of the process.

- Consistent result: High centrifugal force from high-speed “rotation” and “revolution” ensures thorough dispersion. Therefore, every batch can achieve consistent uniformity, leading to reliable performance.

- Efficient defoaming: The high-efficiency vacuum pump can eliminate sub-micron bubbles while the materials are being mixed, in seconds to several minutes. This streamlines the process and ensures a smoother finish and prevents oxidation.

- Wide range of processing: This paint mixer is capable of handling material quantities from as little as 1g up to 7kg, minimizing materials waste. This Scalability makes it ideal for both small sample testing and large-scale production.

- Lower maintenance costs: The paint mixer requires less maintenance because it lacks submerged components that are prone to wear and tear.

The CMV-40 paint mixer excels at blending powder and liquid materials to create high-quality beauty sealants. It is effective for producing beauty sealants for sealing joints, seams and cracks in ceramic tiles, glass structure, and metal structure. The paint mixer’s advanced mixing mechanism ensures uniform consistency and enhanced adhesion of the result:

With a high-efficiency vacuum pump, the CMV-40 can mix materials evenly while simultaneously removing air bubbles in a matter of seconds to minutes. Capable of handling both small and relatively larger batch sizes, this paint mixer is essential for beauty sealant manufacturers looking to optimize their production processes. Additionally, the ability to adjust mixing parameters such as time, speed, and vacuum degree allows for customization to meet specific material requirements.

Choose us, and we promise to do everything needed to ensure a successful and satisfactory working partnership. The 4 reasons set out below will give you an insight into our advantages.

We have over 10 years of industry experience and have a better understanding of the processes involved than most salespeople.

We have sales experience in more than 20 countries worldwide and have a certain understanding of market demand.

We have experienced employees serving you in various aspects such as R&D, manufacturing, sales, and after-sales.

They outperform their competitors when it comes to durability and performance, deeply trusted by both domestic andforeign customers.

This is a planetary centrifugal mixer specifically designed for the rapid mixing of materials

in the beauty sewing industry, during the stirring process, defoaming occurs simultaneously.

Shenzhen Smidalntelligent Equipment Co.Ltd.

Automation Equipment One Stop Solution Provider

Smida is a company with more than 10 years of production and R&D experience in the professional intelligent equipment. It is a national high-tech enterprise

that integrates automation solution consulting, R&D, manufacturing, and after-sales service. We win a number of

foreign trade export certification and patents, and has cooperated with many enterprises.

Step 1: Connect the power, turn on the power switch, and open the

machine cover.

Step 2: Take out the mixing tank and add the corresponding

proportion of primary color material.

Step 3: Install the mixing tank and balance weight into the solder

paste tank.

Step 4: Close the machine cover and set the mixing parameters.

Step 5: Start the start button and the device will start stirring.

Step 6: After the mixing time is over, wait for the mixing bracket to

stop rotating.

Step 7: Remove the mixing tank.

The sewing agent industry, decoration industry and so on

Comparison before and after mixing

After mixing, the material color is uniform and there are no bubbles.

Comparison of Beauty Sealant and Wall Colors

The color of the mixed material is consistent with that of the wall, and there is not much difference.

Filling the effect of beauty sealant on ceramic tiles

When the beauty sealant fills the gaps in the tiles, the colors are very similar.

If you have any further questions about the paint mixer, please contact Smida.

1

Can other materials be mixed?

Sure, but the effect may not be satisfactory.

2

Why is there color difference?

One of the reasons is uneven mixing, but the Smeda paint mixer does not have the phenomenon of uneven mixing.

Company Advantages

· The current international advanced surface treatment technology is used for Smida centrifugal mixer production.

· With the implementation of the improved quality inspection system, the product quality is guaranteed.

· If there is any damage of centrifugal mixer during transportation, Shenzhen Smida Intelligent Equipment Co., Ltd. will take the responsibility.

Company Features

· Known for the standardized production process and high quality, Shenzhen Smida Intelligent Equipment Co., Ltd. has accumulated years of experience and knowledge in manufacturing centrifugal mixer.

· Shenzhen Smida Intelligent Equipment Co., Ltd. has advanced manufacturing equipment and well-established quality assurance system.

· We are always here waiting for your feedback after buying our centrifugal mixer. Please contact us!

Application of the Product

centrifugal mixer developed and produced by Smida is widely applied to many industries and fields. It can fully meet the diversified needs of customers.

Guided by the actual needs of customers, Smida provides comprehensive, perfect and quality solutions based on the benefit of customers.